WITH THE MOST ADVANCED TECHNOLOGY AROUND THE GLOBE: CAN YOUR ALUMINUM SAW KEEP UP WITH THIS?

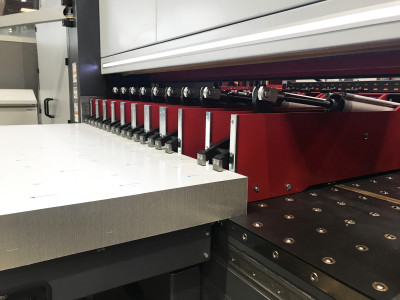

Precision cutting to within a tenth of a millimeter? Cut-to-size without trim-cut? Operation with ease? The Briganto Aluminium Saw can do all of this and much more! An integrated, high-tech measuring system delivers maximum cutting accuracy. A trim-cut is no longer needed. Therefore, time and material are saved.

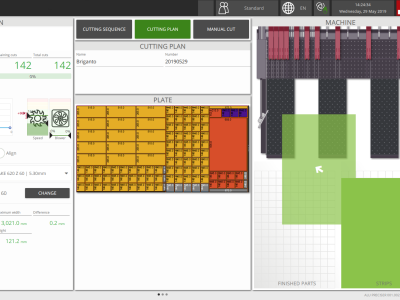

Sophisticated software technology allows for operation of the machine with ease. Within minutes, your team can learn how to operate the saw. A revolutionary chip extraction system collects all the chips and guarantees a clean work environment.

How can this be? We have developed an aluminium saw to be solely used for cut-to-size aluminium. Because of this, the Briganto Aluminium Saw can take care of specific requirements found in the Aluminium Industry.

THE BENEFITS OF OPERATING THE BRIGANTO ALUMINIUM PLATE SAW AT A GLANCE:

- Highest cutting accuracy

- Material and time savings result in lower operating costs

- Easy to operate for everyone

- Robust and durable machine design features

- Clean work environment – most of the chips are extracted

- Material scratches are prevented – the subject “material protection” is taken to a new level

- The highest quality of service with dedicated personal support